In the commercial flooring current market, vinyl flooring has long been a chosen Answer due to its durability, layout adaptability, and cost-performance. having said that, as consciousness bordering material health and environmental security proceeds to grow, companies and suppliers from the vinyl flooring wholesale marketplace need to confront a crucial problem: Is your vinyl flooring genuinely Risk-free?content protection has become One of the more scrutinized areas of flooring merchandise, specifically in industrial environments exactly where usage is intense, and in which purchasers expect not simply efficiency but also very long-expression health and fitness and environmental assurance. From chemical emissions to supply chain transparency, every single aspect inside the output and lifecycle of vinyl flooring is beneath the spotlight.This thorough guideline breaks down The main element dimensions of vinyl flooring protection and offers actionable insights for almost any industrial vinyl flooring provider aiming to future-proof their brand name, secure close-consumers, and continue to be forward of restrictions.

Table of contents:

one. Chemical Emissions: A twin-Phase issue

2. Uncooked substance Selection: Purity Equals basic safety

three. Manufacturing Hygiene: clear Processes for thoroughly clean Products

four. Certifications and Regulatory Compliance

five. Vulnerable Populations: Design for basic safety

6. Long-expression sturdiness and protection

seven. clear Supply Chains: No techniques, No Surprises

one. Chemical Emissions: A Dual-stage problem

Short-Term Emissions soon after Installation

Upon installation, quite a few vinyl flooring merchandise emit volatile natural and organic compounds (VOCs), for instance formaldehyde, toluene, and xylene. These substances add to indoor air pollution and therefore are known to induce respiratory discomfort, complications, and also long-time period medical problems in sensitive persons.

In business Areas like workplaces, retail stores, and healthcare services, indoor air excellent performs a pivotal job in user convenience and security. Preliminary off-gassing can undermine the perceived high-quality of the product and raise issues among the facility administrators and purchasers.

Mitigation technique: inspire the usage of pre-procedure processes like high-temperature curing or pre-set up airing out, which accelerates the discharge of VOCs before the flooring is installed. This can help produce an item that's safer from working day 1.

very long-time period Chemical Leaching

Even following the Preliminary off-gassing subsides, particular chemical compounds can continue to leach eventually. Notably, plasticizers such as DEHP (a kind of phthalate) and major metals like guide and cadmium can migrate from the flooring in the air or dust, especially in higher-warmth or humid environments.

for instance, underfloor heating programs, which might be increasingly popular in commercial properties, can intensify these emissions, bringing about possible health hazards about prolonged exposure.

Mitigation method: husband or wife with brands who definitely have phased out hazardous substances in favor of safer options, for example calcium-zinc stabilizers and non-phthalate plasticizers. These formulations considerably lower extensive-expression chemical publicity.

two. Uncooked Material choice: Purity Equals protection

PVC foundation Resin good quality

the inspiration of vinyl flooring is its polyvinyl chloride (PVC) layer. If this foundation consists of residual vinyl chloride monomer (VCM) or is made out of very low-top quality recycled PVC, it might harbor impurities and unidentified contaminants.

Answer: Commercial customers ought to desire entire transparency within the origin and grade of PVC utilized. Virgin, food items-grade, or health care-grade PVC resins make sure a clear starting point and decrease hazards related to recycled or contaminated Uncooked supplies.

Protected Additives and Stabilizers

Vinyl flooring goods contain various additives—plasticizers, stabilizers, flame retardants, UV absorbers—that add to functionality. But a lot of of these additives are also recognized to contain substances of concern, which include BPA or halogenated flame retardants.

Alternative: function with companies who prioritize bio-dependent plasticizers, such as soybean oil derivatives, and non-halogenated flame retardants like magnesium hydroxide or aluminum hydroxide. These products sustain hearth resistance and adaptability even though eliminating toxicity worries.

three. producing Hygiene: Clean Processes for thoroughly clean solutions

Residual Solvents and Byproducts

Vinyl flooring manufacturing generally consists of solvents and chemical processes that could go away powering residues if not effectively managed. Substances like acetone, methyl ethyl ketone, or unreacted monomers may very well be trapped in the final solution.

Option: Partner only with suppliers who use closed-loop manufacturing units with solvent recovery fees previously mentioned ninety five%. These techniques lower squander, boost air top quality, and reduce leftover chemical residues while in the flooring.

Cross-Contamination in Shared Facilities

amenities that make several item lines may pose a chance of cross-contamination, particularly if harmful substances (e.g., asbestos-centered products) are taken care of nearby.

Option: Insist on devoted creation strains or isolated workshops for vinyl flooring products. trustworthy suppliers should also give 3rd-get together certification experiences validating the cleanliness and purity of their facilities.

4. Certifications and Regulatory Compliance

world-wide Environmental Certifications

attaining certifications like GREENGUARD Gold or Blue Angel is a strong way for suppliers to differentiate their solutions. These certifications confirm compliance with stringent emission thresholds and environmental security criteria in the course of a product’s lifecycle.

For GREENGUARD Gold, flooring need to satisfy really lower VOC emission restrictions, rendering it suited to use in colleges, hospitals, and Business office environments. Blue Angel goes further more by analyzing resource effectiveness, material recyclability, and end-of-daily life impression.

Regional authorized prerequisites

each and every commercial vinyl flooring supplier must keep updated with world-wide and regional regulations. The European Union’s arrive at laws, for example, maintains an index of Substances of Very large Concern (SVHC), which now consists of much more than 200 compounds. In China, criteria like HJ 2502-2010 element necessities for eco-pleasant flooring.

Alternative: on a regular basis audit solutions towards get to, RoHS, and other applicable environmental criteria. If the products is exported globally, compliance ought to prolong past the minimum amount domestic necessity.

reasonable tests Scenarios

a lot of flooring goods pass laboratory emissions checks less than excellent problems, but are unsuccessful in serious-entire world eventualities for instance substantial-humidity or floor-heated environments.

Answer: Request emissions testing under simulated use circumstances—e.g., 28°C temperature with 65% relative humidity—to acquire a realistic emissions profile. Use this details to guideline buyers and bolster transparency.

five. Vulnerable Populations: structure for security

baby and Maternal well being

Phthalates and equivalent substances are acknowledged endocrine disruptors which will impact hormone development in fetuses and youngsters. In spaces like daycares, hospitals, and educational institutions, flooring need to be Secure for probably the most vulnerable populations.

Answer: Choose flooring that complies with U.S. CPSC (customer products security Commission) expectations for kids’s solutions. Products must be free of charge from phthalates and also other suspected endocrine disruptors.

Allergen-free of charge efficiency

steel ions like nickel and cobalt, from time to time present in floor coatings, might cause pores and skin reactions or allergic reactions. On top of that, antimicrobial agents including triclosan can bring about sensitivities.

Alternative: Look for flooring Qualified as hypoallergenic and analyzed by impartial dermatological labs (e.g., Dermatest). item packaging or requirements must Obviously talk allergy-friendly standing.

6. extended-time period toughness and protection

Environmental Resistance

As resources age, their chemical security can shift—especially in harsh environments. In warm and humid industrial spaces, some flooring items may begin to emit extra VOCs as time passes.

Resolution: Insist on multi-atmosphere screening that simulates yrs of put on under diverse ailments, like forty°C and ninety% humidity. Use these results to demonstrate the prolonged-term steadiness and safety of the choices.

Resistance to Abrasion and problems

eventually, use and tear over the surface area layer may expose fundamental supplies. If those deeper levels aren't as chemically secure, This could certainly boost emissions or expose harmful substances.

Remedy: boost monolithic vinyl buildings in lieu of multi-layer laminates. A fully compact, non-layered materials composition maintains integrity much better less than mechanical worry.

7. clear Supply Chains: No techniques, No Surprises

Uncooked content Traceability

An increasing variety of commercial buyers are demanding total traceability For each and every ingredient of the solutions they obtain. This consists of plasticizers, PVC resin, flame retardants, and stabilizers.

Remedy: make sure your upstream suppliers maintain certifications for instance ISO 9001 and provide documentation on raw substance origin. complete source chain mapping is now not optional—it’s the sector website typical.

Packaging security

Even packaging resources make any difference. Some vinyl flooring is shipped working with recycled plastics which will leach hazardous substances into your product through storage or transportation.

Alternative: pick pure polyethylene (PE) packaging and steer clear of using non-Qualified recycled resources. Make packaging basic safety a visible section within your high-quality promise.

Strategic protection steps for professional Vinyl Flooring Suppliers

to take care of Management and obtain belief from the vinyl flooring wholesale marketplace, Listed here are various essential steps each supplier should just take:

determine and Publish a Safety Threshold checklist

contain formaldehyde (≤0.05 mg/m³), phthalates (≤0.1%), as well as other chemical boundaries. Make this list obvious on your website or in products documentation.

keep an eye on and Adapt to international restrictions

keep forward of impending changes in legal guidelines like arrive at, CLP, or the U.S. TSCA. Regulatory readiness will give you a competitive edge.

employ clever Transparency Tools

incorporate QR codes on packaging or merchandise internet pages that connection to VOC emission graphs, certification scans, and 3rd-celebration lab studies. This visual information builds buyer self-confidence.

In the fashionable industrial atmosphere, flooring will have to do in excess of appear great or very last lengthy. It have to be Protected—instantly and after a while—for everybody who will come into contact with it.materials security is no more an include-on; it’s a Main function. For suppliers who prioritize chemical transparency, accountable manufacturing, and extensive-phrase health, the payoff is obvious: brand trustworthiness, customer loyalty, and regulatory security.manufacturers like eco-friendly stage have taken the lead by applying these procedures and presenting business vinyl flooring methods that reflect the very best basic safety and environmental criteria. For every professional vinyl flooring supplier aiming to thrive in the subsequent decade, adhering to this design is not only recommended—it’s vital.

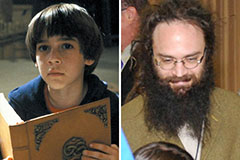

Barret Oliver Then & Now!

Barret Oliver Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Kane Then & Now!

Kane Then & Now!